Solar Solutions Channel Consulting Services

Advisory for Alternative Renewable Energy

- Renewable Energy Concepts

- Governments / Power Provider

- Analysis / Recommendations

PV Laboratory Design Implementation and Accreditation

- National Lab

- PV Module Test

- ISO 17025

- Equipment / Materials

Training and Education PV Technology

- PV Solar Technology

- Manufacturing

- Testing

PV Technology Transfer Start up Services

- Materials

- Localization

- Start Up

PV Manufacturing Set Up

- Pilot Plants

- Turn Key Solutions

- Equipment / Materials

PV Power Plants

- Design / EPC

- Turn Key Solutions

- Rural Solutions

- On Grid, Off Grid

Advisory for Alternative Renewable Energy

- Advisory to governments, regions and electricity provider for improving the power situation especially with continued demand for more electricity supply

- Analysis of power demand versus supply in specially effected regions

- Analysis of economics with various power options in comparison with PV Solar

- Proposal for decentralized PV power stations to reduce or eliminate power outages

- Proposal for powering rural areas with no availability of electricity with small power stations or individual home power systems for individual households

- On grid and off grid PV solutions

PV Laboratory Design Implementation and Accreditation

- Besides training and education, setting up testing capability for PV Solar components is key. It is essential to determine the quality and reliability of products coming into the country.

- Analyzing the quality of PV modules can be done with a small number of key types of testing equipment.

- Solar Solutions Channel can develop a roadmap to start with a minimum essential set of testing equipment to a fully capable PV Module testing laboratory complying with standards such as IEC 61215 and IEC 61730.

- The company, in partnership with expert organizations, can provide training and assist in setting up a PV lab organization leading to an internationally recognized accreditation such as ILAC-MRA.

- The company can assist the PV laboratory in developing dedicated protocols for addressing local deviations and conditions.

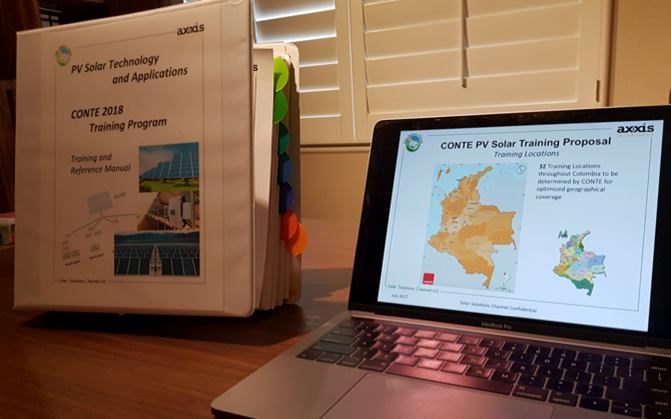

Training and Education PV Technology

- Customized training and educational programs, to enhance knowledge of local personnel on the principals of PV solar technologies and its use. The aim is to build localization and local expertise.

- Training programs may include introduction to:

- Various Solar technologies, advantages and disadvantages

- PV Solar power plants on grid and off grid

- Introduction to PV Module manufacturing techniques

- PV Solar manufacturing facility certification (ISO 9001:2014)

- PV Module quality and reliability, PV test laboratories and related test standards

- Hands on training for new PV module manufacturing facilities, development of manufacturing processes including material management

- PV Laboratory, path to accreditation ISO 17025)

PV Technology Transfer Start Up Service

Support for existing Manufacturing Lines

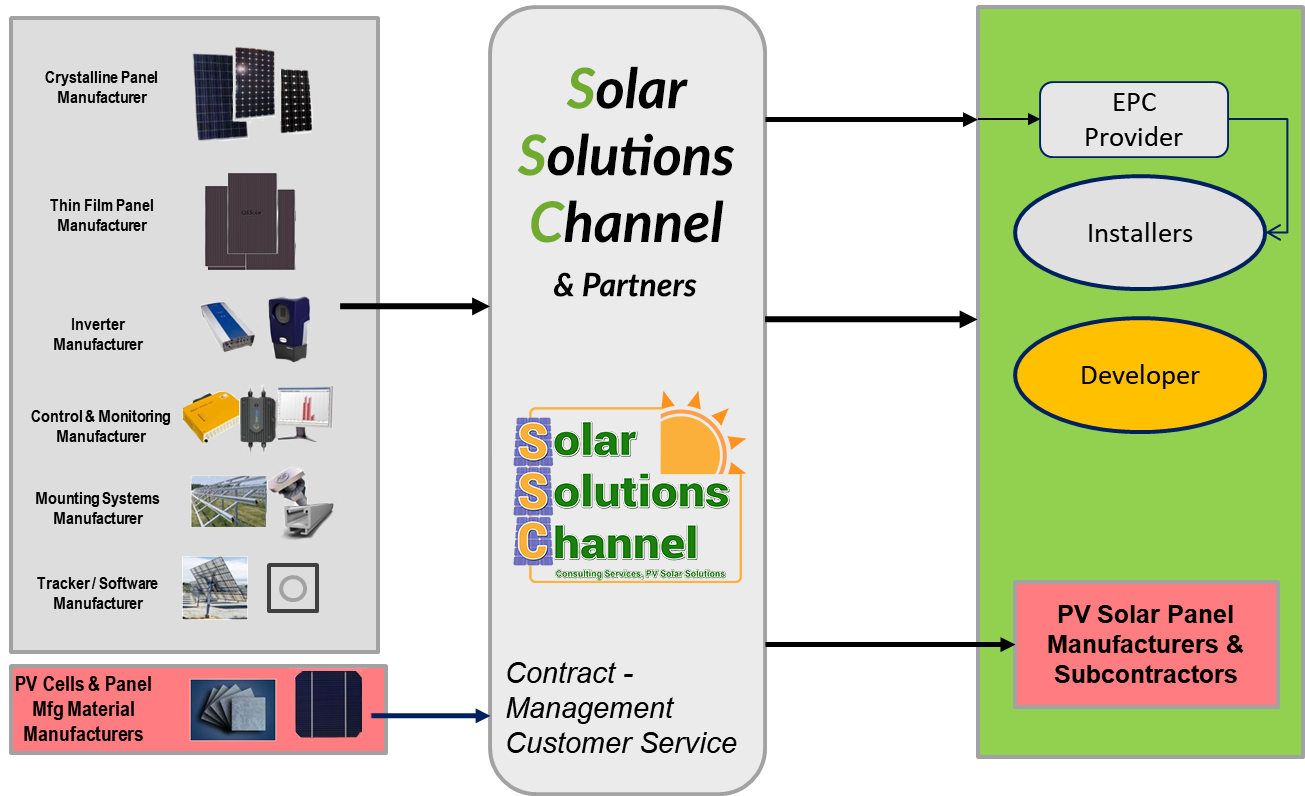

- In working with partners and through our consulting services and PV solar solutions activities we have developed and maintain significant contacts into the global PV solar industry and supplier base. For new companies or existing companies branching into the PV solar business, we are offering the following services:

-

- Finding the right supplier base for their needs

- Assisting through the product qualification phase

- Setting up supply contracts for production ramp and production phase

- Contract management

- For suppliers we can act as their Manufacturer’s Representative

- Consulting

- If you are planning to set up a manufacturing line for PV wafer, cells, modules or thin film modules, operational excellence will make the difference as to whether you are producing successfully and profitable or not. It starts with selecting the right manufacturing equipment for the task and continues with negotiating optimized equipment specifications and support conditions with the vendors to ensure best conditions for the line. Further, optimized integration over all equipment suppliers is key. Finally to set up a cost-optimized, cross-trained maintenance structure with fast access to consumable and non-consumable spare parts, completes the scenario.

- If you are running a semiconductor or PV solar manufacturing line and want to improve output and performance, we can help you to analyze your current structure and business processes for better efficiency, performance improvement and cost reduction

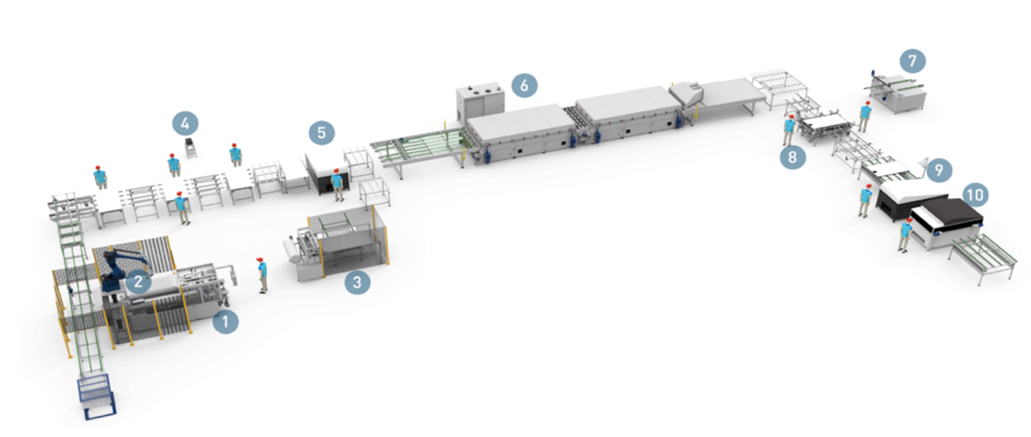

Support for New Manufacturing Lines

- New PV Solar manufacturing line planning support for wafer, cell and module lines

- Equipment and vendor selection support

- Equipment specification negotiation specifically with regard to uptime performance and maintenance support

- Development of an integrated maintenance structure across all equipment and equipment vendors to ensure overall factory efficiency

- Develop best spare parts (consumable and non-consumable) concept for minimized inventory cost, yet optimized performance

- Set up maintenance structure

- Analyze current maintenance operation for structural and logistical improvements

- Find alternative spare parts supplier for operational cost reduction and / or equipment performance improvement

- Engineering Consultation, efficiency improvement

PV Manufacturing Set Up

- Transferring technology and setting up manufacturing facilities for PV Solar components such as PV Modules of various technologies, c-Si Cell manufacturing, DC-AC inverter.

- The size may vary from small pilot manufacturing lines for technology transfer and developing local expertise through high volume manufacturing facilities for output.

- The company’s service starts with supplying individual equipment through turn key solutions including sourcing of expert labor, training, commissioning, development of RAW material sources for volume manufacturing and competitiveness

- Install quality and reliability through development of distinct processes and factory certification ISO 9001:2014…

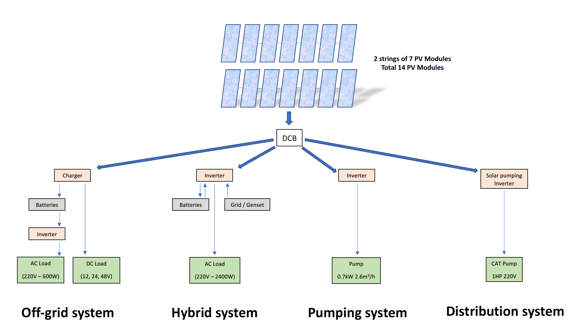

PV Power Plants

- PV power plant designs including EPC (Engineering Procurement and Construction) management

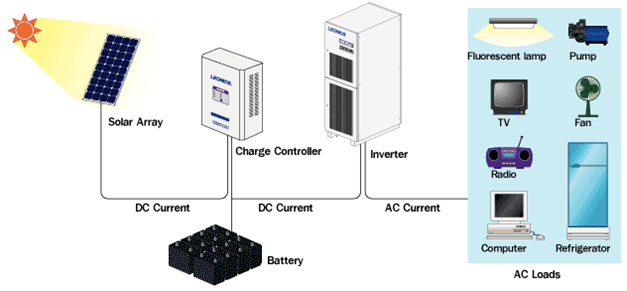

- Small off grid individual PV power stations for single houses, with optional inclusion of accessories, lighting…

- The aim for small stations is to provide un-interrupted electricity. The system should include electricity storage for a limited number of days with no power generation (cloudy, rainy days)

- Off grid PV power stations of larger size with optimized share of localization

- On grid PV power stations of larger size with optimized share of localization

- PV power station designs will be conducted in partnership with experienced companies having implemented multiple alike projects

- Building local expertise through these projects is key, including construction, material sourcing, operation and maintenance